TECTYL® 930E2

INTERNAL COMBUSTION ENGINE OIL AND CORROSION PREVENTIVE

Tectyl 930E2 General Information:

MEETS MILITARY SPECIFICATION MIL-PRF-21260E.

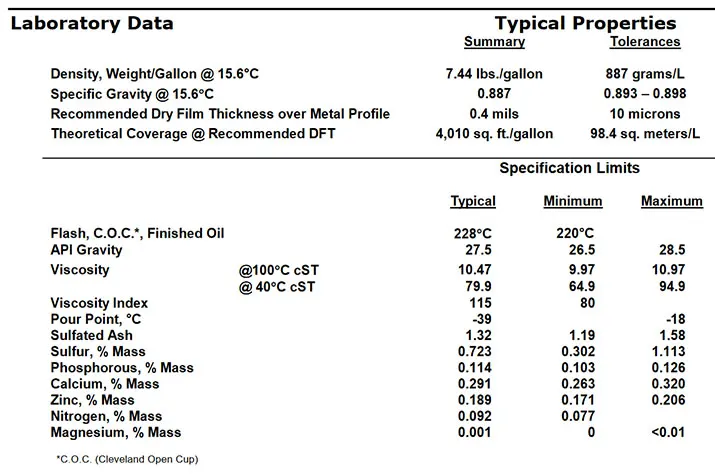

TECTYL® 930E2 is an internal combustion engine oil and corrosion preventive for all new and rebuilt engines. The film is oily and translucent. As a preservative oil, TECTYL® 930E2 protects engine parts during covered shipment and indoor storage. TECTYL® 930E2 is approved under Military Specification MIL-PRF-21260E.MIL-PRF-21260E, Grade 30, and has QPL Reference Number MP-405, and SAE Standard J2361, PRI QPL Number PRI EO 0044.

TECTYL 930E2 Application:

TECTYL 930E2 is formulated to be used as supplied.

Ensure uniform consistency prior to use. Continued stirring is generally not required. If the product thickens due to cold storage or loss of solvent during use, contact Daubert Chemical Company.

DO NOT THIN TECTYL 930E2. Incorrect thinning will affect film build, dry time and product performance.

Daubert Chemical Company recommends that the ambient and product temperature be 50 - 95°F (10 - 35°C) at time of application.

TECTYL 930E2 should be used as factory fill and break-in oil for all new and rebuilt engines. This is a completely operational oil for current production engines meeting the requirements of MIL-PRF-21260E and need not be changed until the first scheduled oil change specified by engine manufacturer.

As a preservative coating, TECTYL 930E2 is used to protect engine parts during covered shipment and indoor storage. TECTYL 930E2 is compatible with lubricating oils qualified under MIL-PRF-21260E, MIL-PRF- 2104, and MIL-L-46152E.

TECTYL 930E2 Surface Preparation:

The maximum performance of TECTYL 930E2 can be achieved only when the metal surfaces to be protected are clean, dry, and free of rust, oil, and mill scale.

Daubert Chemical Company recommends that the metal substrate temperature be 50 - 95°F (10 - 35°C) at the time of product application.

TECTYL 930E2 Storage:

Store TECTYL 846, Class I at temperatures between 50-95°F (10-35°C). Mild agitation is recommended prior to use.

TECTYL 930E2 Removal:

TECTYL 930E2 can be removed with TECTYL HPS solventborne thinner, vapor degreasing, or low pressure steam. TECTYL 930E2 can be removed from fabrics by normal dry cleaning procedures. Avoid the use of chlorinated or highly aromatic solvents when removing from painted surfaces, as these solvents may adversely affect paint.

TECTYL 930E2 Caution:

Refer to Daubert’s Material Safety Data Sheet for health and safety information

TECTYL 930E2 Note:

The addition of any product over or under this coating is not recommended. The use of additional coatings could result in chemical incompatibility, thus adversely affecting the performance of this coating as stated in the lab data section. If a product other than Daubert Chemical Company's recommended product is required, written authorization must be obtained from Daubert Chemical Company.

Recommendations set forth in this product information sheet are based on testing, research and other development work which has been carefully conducted by Daubert Chemical Company, and they believe such data, statements and recommendations will serve as reliable guidelines. However, this product is subject to numerable uses under varying conditions over which they have no control, and accordingly, we do NOT warrant that this product is suitable for any particular use. Users are advised to test the product in advance to make certain it is suitable for their particular production conditions and particular use or uses.

Recommendations set forth in this product information sheet are based on testing, research and other development work which has been carefully conducted by Daubert Chemical Company, and they believe such data, statements and recommendations will serve as reliable guidelines. However, this product is subject to numerable uses under varying conditions over which they have no control, and accordingly, we do NOT warrant that this product is suitable for any particular use. Users are advised to test the product in advance to make certain it is suitable for their particular production conditions and particular use or uses.

TECTYL 930E2 Warranty:

Daubert Chemical Company, Inc. (“Daubert©?) warrants all products manufactured by it to be free from defects in material and workmanship. DAUBERT MAKES NO OTHER WARRANTIES, WHETHER, EXPRESSED OR IMPLIED, WITH RESPECT TO SUCH PRODUCTS, AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND IMPLIED WARRANTIES ARISING FROM A COURSE OF DEALING OR USAGE OF TRADE, ARE DISCLAIMED BY DAUBERT.

All claims hereunder must be made in writing within 30 days after receipt of the products at the buyer’s plant and prior to further processing the products or combining them with other materials or products. Daubert’s liability, whether under this warranty or in contract, tort, negligence or otherwise, is limited to the return of the net purchase price paid for any products proven defective or, at Daubert’s option, to the repair or replacement of said products upon their return, transportation prepaid, to Daubert. THE REMEDY HEREBY PROVIDED SHALL BE THE EXCLUSIVE AND SOLE REMEDY OF THE BUYER, AND UNDER NO CIRCUMSTANCES SHALL DAUBERT BE LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Daubert representative or other person is authorized to change this warranty in any way or to assume for Daubert any other liability in connection with the sale or use of its products. REFER TO Material Safety Data Sheet FOR HEALTH AND SAFETY INFORMATION.