TECTYL® 275

WATER DISPLACING, SOLVENT CUTBACK CORROSION PREVENTIVE COMPOUND, LUBRICANT, AND PENETRANT.

TECTYL® 275 is available in 5 gallon pails, and in 55 gallon drums.

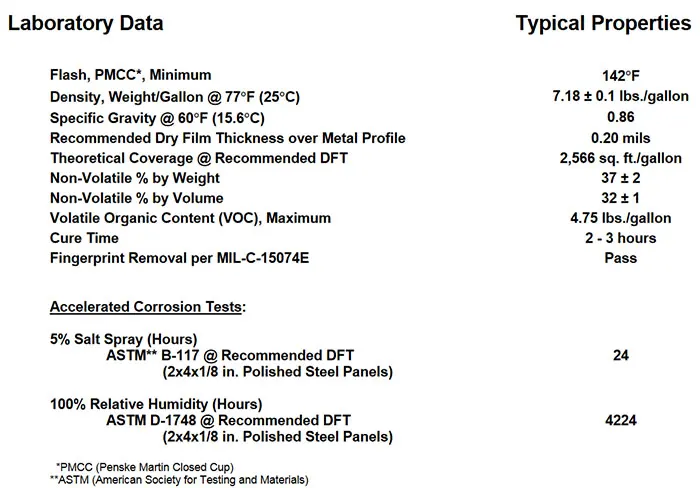

TECTYL® 275 Properties

TECTYL 275 is a water displacing, solvent cutback corrosion preventive compound, lubricant, and penetrant. The Tectyl 275 film is an ultralight, transparent oil that has fingerprint suppressor and removal capabilities. TECTYL 275 is approved under Military Specification MIL-C-15074E. TECTYL 275 provides protection for industrial parts and transportation components.

TECTYL® 275 Surface Preparation

The maximum performance of TECTYL 275 can be achieved only when the metal free of rust, oil and mill scale. The metal substrate temperature should be 50-95°F (10-35°C) at the time of product application.

TECTYL® 275 Application

TECTYL® 275 is formulated to be used as supplied. Ensure uniform consistency prior to use. Continued stirring is generally not required. If the product thickens due to cold storage or loss of solvent during use, contact Daubert Chemical Company. DO NOT THIN TECTYL® 275. Incorrect thinning will affect film build, dry time and product performance.

Daubert Chemical Company recommends that the ambient and product temperature be 50 - 95°F (10 - 35°C) at time of application.

TECTYL® 275 Storage

Store TECTYL 275 at temperatures between 50-95°F (10-35°C). Mild agitation is surfaces to be protected are clean, dry and recommended prior to use.

TECTYL® 275 Removal

TECTYL 275 can be removed with TECTYL HPS solventborne thinner, vapor degreasing, hot alkaline wash, or low pressure steam.

TECTYL 275 can be removed from fabrics by normal dry cleaning procedures. Avoid the use of chlorinated or highly aromatic solvents when removing from painted surfaces, as these solvents may adversely affect paint.

TECTYL® 275 Caution

The data, statements and recommendations set forth in this product information sheet are based on testing, research and other development work which has been carefully conducted.

We believe such data, statements and recommendations will serve as reliable guidelines. However, this product is subject to numerable uses under varying conditions over which we have no control, and accordingly, we do NOT warrant that this product is suitable for any particular use.

Users are advised to test the product in advance to make certain it is suitable for their particular production conditions and particular use or uses.

REFER TO MATERIAL SAFETY DATA SHEET FOR HEALTH AND SAFETY INFORMATION.

TECTYL® 275 Note

The addition of any product over or under this coating is not recommended.

The use of additional coatings could result in chemical incompatibility, thus adversely affecting the performance of this coating as stated in the lab data section.

If a product other than Daubert Chemical Company's recommended product is required, written authorization must be obtained from Daubert Chemical Company, Inc.