CASTROL Brayco 602EF

NLGI #2 Grease

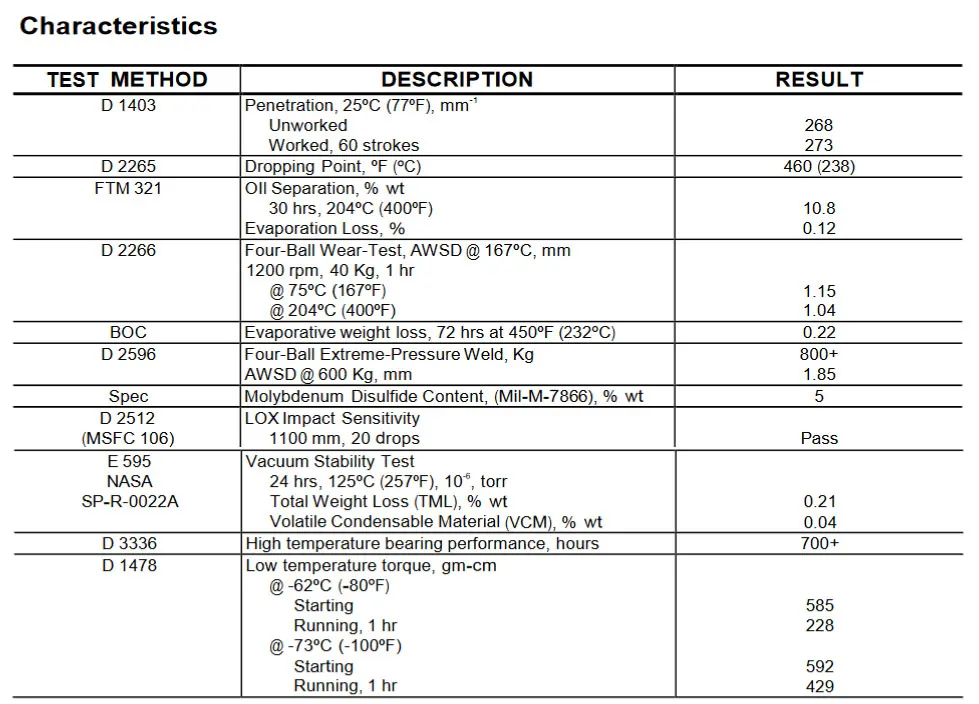

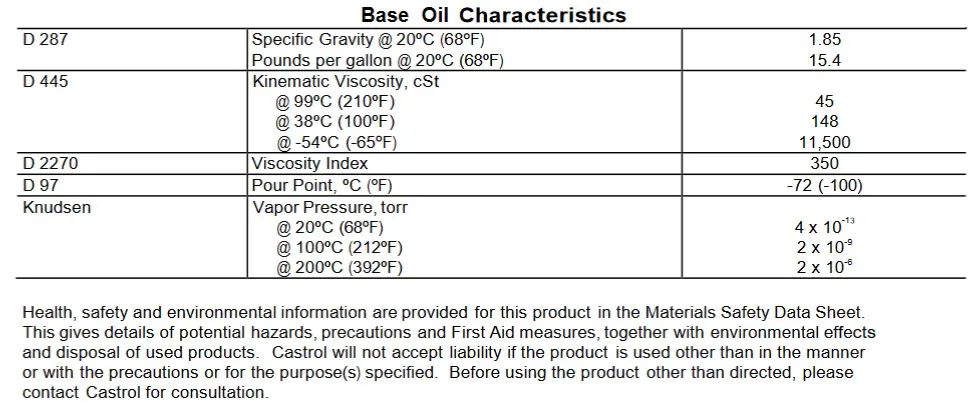

Castrol Braycote 602 EF is a smooth, buttery, gray colored NLGI #2 grease. The base fluid(CastrolBrayco®815Z) is a stable perfluorinated polyether with exceptional chemical resistance, extremely low volatility, and a wide temperature service range. The gelling agent is a tetrafluoroethylene telomer. This grease contains molybdenum disulfide. This product is nonflammable, does not use any chlorofluorocarbons(CFC's) during product manufacture, and is in general, chemically inert. It is an excellent lubricant, has good shear stabilit y, and low acute toxicity. Castrol Fluoroclean™ X100 or Castrol Fluoroclean™ HE can be used to remove this lubricant. Refer to the data sheets for these products for more information.

The recommended operating temperature range for MIL-PRF-7808 type oils are from –54°C to 149°C (-65°F to 300°F).

Brayco 602 EF Application

Braycote 602 EF is designed to operate in the presence of fuels, oxidi zers, and deep space vacuums. Typical applications include ball and roller bearings, gears, electrical contracts, and as an assembly lubricant for O- rings and elastomers. This grease is highly recommended in applications where temperature extremesand/or low vacuums are routine. Perflu orinated greases, such as this product, exhibit excellent shelf life due to their intrinsic inertness.

Brayco 602EF Limitations

Braycote 602 EF is compatible with most commonly utilized materials, plastics, and elastomers. It may be adversely affected by Lewis Acid catalysts such as aluminum chloride, at elevated temperatures.Newly exposed rubbing surfaces of aluminum, magnesium or titanium alloys may react with this product under certain conditions. Such systems should be thoroughly evaluated. Surfaces must be well cleaned of organicrust inhibitors prior to grease application to insure proper lubrication. This product is not recommended for use in applications under high vacuum with loads exceeding 100,000 psi for extended periods of time.

Brayco 602EF Packaging

Braycote 602 EF is packaged in 2 oz (AVDP) and 4 oz disposable plastic syringes and 1 pound jars.Castrol Braycote 602 EF07.15.2005, Version Number 2.0 Braycote 602EF and the Castrol logo are trademarks of Castrol Limited. All reasonable care has been ta ken to ensure that the information contained in this publication is accurate as of the date of printing. However, such information may, nevertheless, be affected by changes in the blend formulation occurring subsequent to the date of printing. Material Safety Data Sheets are available for all Castrol Ltd products. The MSDS mustbe consulted for appropriate information regarding storage, safe handling and disposal of a product.

Health, safety and environmental information are provided for this product in the Safety Data Sheet. This gives details of potential hazards, precautions and First Aid measures, together with environmental effects and disposal of used products. Castrol will not accept liability if the product is used other than in the manner or with the precautions or for the purpose(s) specified. Before using the product other than directed, please contact Castrol for consultation.