CASTROL Brayco Micronic 783

Hydraulic Fluid, Petroleum Base, For Preservation and Operation

QC Lubricants carries Castrol Brayco® Micronic 783 in 55 gallon drums.

Brayco Micronic 783 Description

Castrol Brayco® Micronic 783 is a petroleum-based, low viscosity, ISO grade 15 red colored hydraulic and preservative fluid for aircraft and ordnance use. It is a blend of selected petroleum oils with additives which provide exceptionally good viscosity-temperature characteristics, good anti-wear properties, controlled rubber swell, good shear stability and excellent oxidation resistance. Castrol Brayco® Micronic 783 is an excellent corrosion preventative and provides a high degree of detergency to maintain clean systems.

Brayco Micronic 783 Uses

Castrol Brayco® Micronic 783 is designed for aircraft, ordnance and other general hydraulic use, and for preserving hydraulic components over a temperature range of -54ºC to 135ºC (-65ºF to 275ºF). It may be used as an operational preservative fluid for all tactical and support ordnance intended for use in MIL-PRF-5606 service. Castrol Brayco® Micronic 783 can be used in hydraulic systems of missile ground support equipment and is particularly suitable for use in systems with long periods of inactivity during service.

BRAYCO MICRONIC 783 Compatibility

Castrol Brayco® Micronic 783 is generally used with standard synthetic rubber "L". This petroleum base fluid may be used with conventional oil and grease resistant paints. Castrol Brayco® Micronic 783 as all other MIL-PRF-6083 fluids should only be mixed with MIL-PRF-5606, MIL-PRF-46170 Type I and MIL-PRF-83282 fluids. Specification Brayco Micronic 776RP meets stringent specifications that have been accepted as contractual requirements with various OEM users.

BRAYCO MICRONIC 783 Scecifications

Castrol Brayco® Micronic 783 meets the requirements of and is qualified to MIL-PRF-6083F. It also meets the requirements for a P-15 preservative under packaging specification MIL-P-116. This fluid is identified by Military Symbol: OHT and NATO Code Number: C-635.

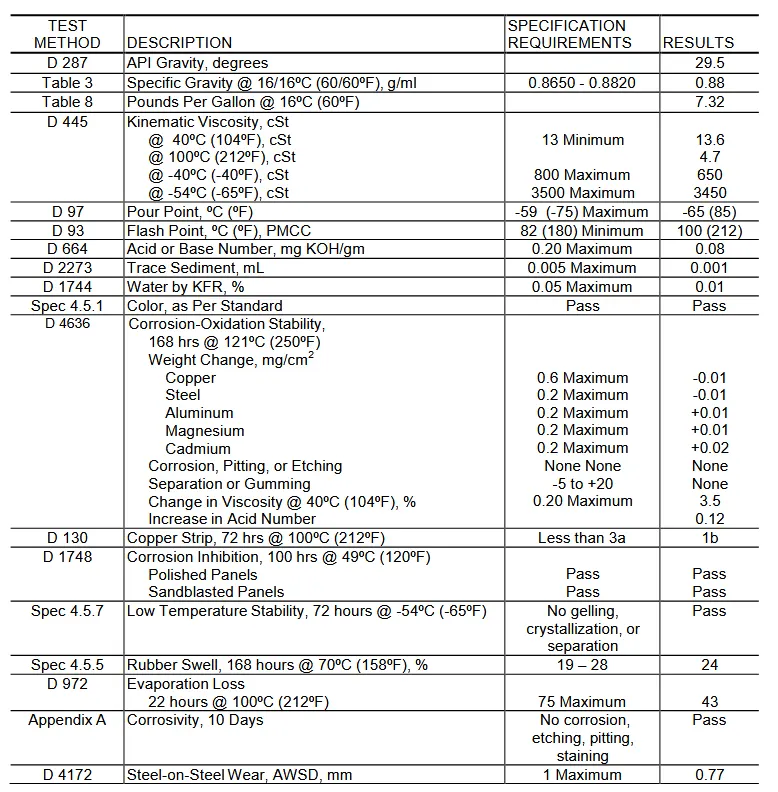

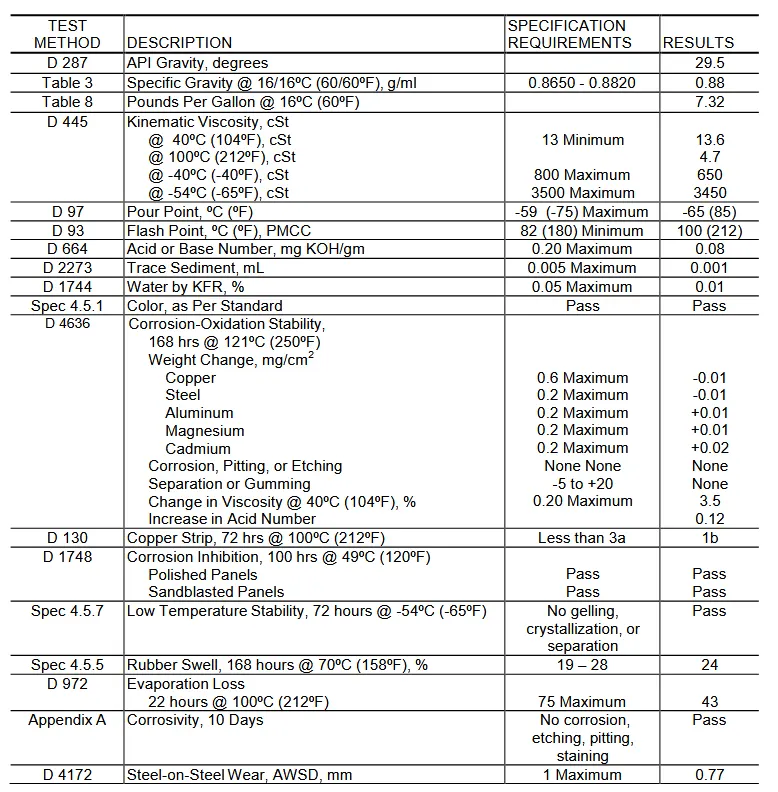

BRAYCO MICRONIC 783 Typical Properties

Castrol Brayco® Micronic 783 is a petroleum-based, low viscosity, ISO grade 15 red colored hydraulic and preservative fluid for aircraft and ordnance use. It is a blend of selected petroleum oils with additives which provide exceptionally good viscosity-temperature characteristics, good anti-wear properties, controlled rubber swell, good shear stability and excellent oxidation resistance. Castrol Brayco® Micronic 783 is an excellent corrosion preventative and provides a high degree of detergency to maintain clean systems.

Brayco Micronic 783 Uses

Castrol Brayco® Micronic 783 is designed for aircraft, ordnance and other general hydraulic use, and for preserving hydraulic components over a temperature range of -54ºC to 135ºC (-65ºF to 275ºF). It may be used as an operational preservative fluid for all tactical and support ordnance intended for use in MIL-PRF-5606 service. Castrol Brayco® Micronic 783 can be used in hydraulic systems of missile ground support equipment and is particularly suitable for use in systems with long periods of inactivity during service.

BRAYCO MICRONIC 783 Compatibility

Castrol Brayco® Micronic 783 is generally used with standard synthetic rubber "L". This petroleum base fluid may be used with conventional oil and grease resistant paints. Castrol Brayco® Micronic 783 as all other MIL-PRF-6083 fluids should only be mixed with MIL-PRF-5606, MIL-PRF-46170 Type I and MIL-PRF-83282 fluids. Specification Brayco Micronic 776RP meets stringent specifications that have been accepted as contractual requirements with various OEM users.

BRAYCO MICRONIC 783 Scecifications

Castrol Brayco® Micronic 783 meets the requirements of and is qualified to MIL-PRF-6083F. It also meets the requirements for a P-15 preservative under packaging specification MIL-P-116. This fluid is identified by Military Symbol: OHT and NATO Code Number: C-635.

BRAYCO MICRONIC 783 Typical Properties