Castrol Braycote 601 EF

Castrol Braycote 601 EF is a smooth, buttery, translucent, off-white, NLGI #2 grease.

Braycote 601 EF Description

Castrol Braycote 601 EF is a smooth, buttery, translucent, off-white, NLGI #2 grease. Its base oil ( Castrol Brayco® 815Z ) is

a perfluorinated polyether, with exceptional chemical resistance, extremely low volatility, and a wide temperature service

range. The grease is non-toxic, nonflammable, and does not use any chlorofluorocarbons (CFC' s ) during product

manufacture. This product exhibits unusually high load- c arrying capabilities as measured by the Four-Ball EP Test, and

contains a rust and corrosion inhibitor for extra component protection. Castrol Fluoroclean™ X100 or Castrol Fluoroclean™

HE can be used to remove this lubricant. Refer to the data sheets for these products for information regarding these

products. Braycote 601EF with molybdenum disulfide is also available for applications requiring both corrosion and extreme pressure additive.

Braycote 601 EF Temperature Range

-80ºC to 204ºC (-112ºF to 400ºF)

Braycote 601 EF Uses

Braycote 601 EF is designed to operate in the presence of rocket fuels and oxidizers and high vacuum. It is frequently used

in space applications including the Space Shuttle and satellites. It should also be considered in any application where a

hostile chemical or extreme environmental conditions would preclude the use of an ordinary grease. Typical applications

include ball and roller bearings, gears, and as an assembly lubricant for

O-rings and elastomers. Perfluorinated greases, such as this product, exhibit excellent shelf life due to their intrinsic inertness.

Braycote 601 EF Limitations

Braycote 601 EF is compatible with most commonly utilized materials, plastics, and elastomers. It may be

adversely affected by Lewis Acid Catalysts such as aluminum chloride, at elevated temperatures. Newly

exposed rubbing surfaces of aluminum, magnesium and titanium alloys may react with this product under

certain conditions. Such systems should be thoroughly evaluated. Surfaces must be well cleaned of orga nic

rus t inhibitors prior to grease application to insure proper lubrication. This product is not recommended for use

in applications under high vacuum with loads exceeding 100,000 psi for extended periods of time.

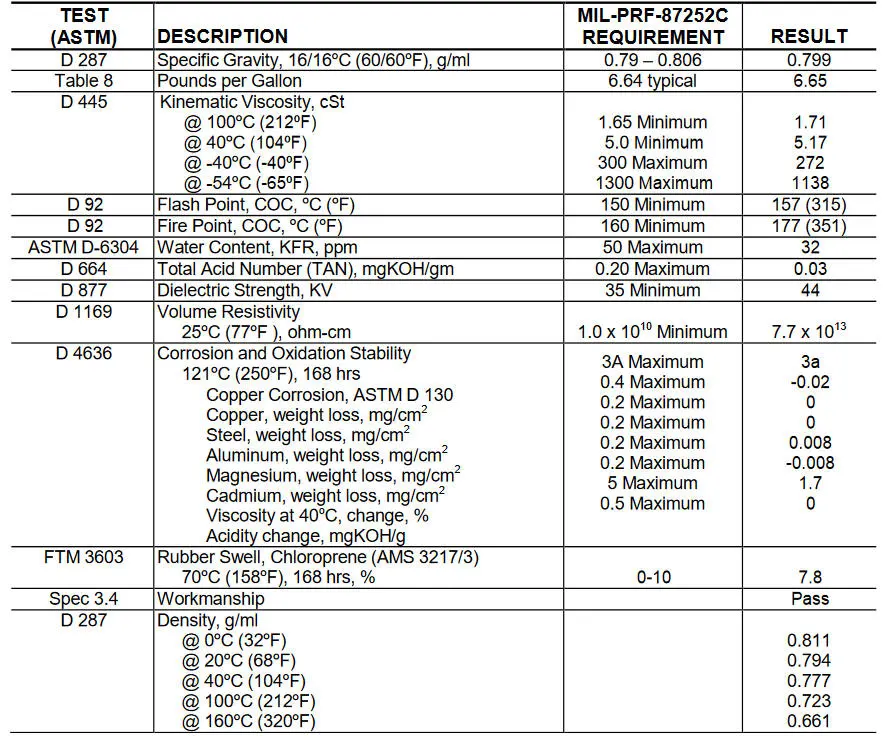

Braycote 601 EF Typical Properties

Health, safety and environmental information are provided for this product in the Materials Safety Data Sheet.

This gives details of potential hazards, precautions and First Aid measures, together with environmental ef f e cts

and disposal of used products. Castrol will not accept liability if the product is used other than in the manner

or with the precautions or for the purp ose(s ) specified. Before using the product other than directed, please

contact Castrol for consultation.