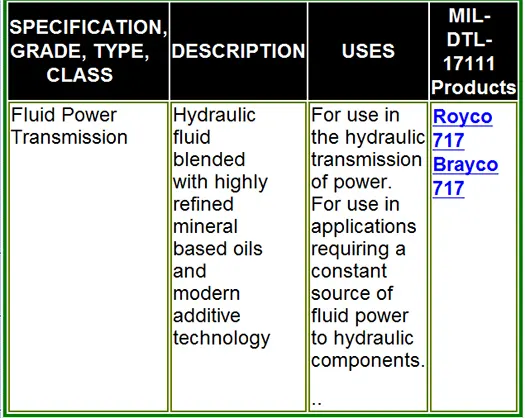

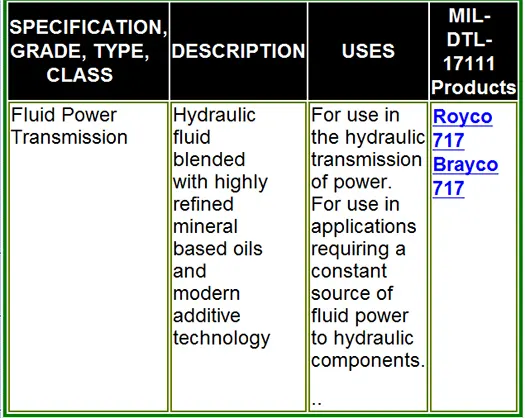

This

hydraulic fluid is blended with highly refined mineral based

oils and modern additive technology to provide protection

against rust, wear, demulsibility, and to afford greatly

improved viscosity - temperature characteristics as well as

enhanced oxidation – corrosion resistance.

This

hydraulic fluid is blended with highly refined mineral based

oils and modern additive technology to provide protection

against rust, wear, demulsibility, and to afford greatly

improved viscosity - temperature characteristics as well as

enhanced oxidation – corrosion resistance.

MIL-DTL-17111C SCOPE:

This specification covers a class of

fluid for use in the hydraulic transmission of power.

MIL-DTL-17111C Intended Use

The fluid covered by this

specification is a medium to be used in connection with

hydraulic transmission power.

MIL-DTL-17111C Subject

term listing

Subject terms listings are Hydraulic mineral

oil, petroleum, and icresyl phosphate.

MIL-DTL-17111C

Materials

The fluid shall consist of mineral oil products

plus 1.0 ± 0.1 weight percent of tricresyl phosphate

conforming to TT-T-656 and approved additive materials for

improving the finished product with respect to the

viscosity-temperature and lubricating characteristics,

resistance to oxidation, and protection of metal parts against

corrosion.

MIL-DTL-17111C Suitability

The fluid

shall be suitable for use in hydraulic systems involving

mechanical or fibrous type filters or centrifugal

purification. It shall be noncorrosive to bearings and

hydraulic systems and shall not cause clogging of oil screens

or valves. The fluid shall remain homogeneous over the

temperature range of -34 °C to 4 °C.

MIL-DTL-17111C Low

temperature turbidity

A dry sample of the fluid shall be

stored at a temperature of 37 °C for not less than 72 hours.

After that time at the storage temperature, the fluid shall

show no evidence of gelling, crystallization, or separation,

and shall develop a turbidity not greater than that exhibited

by a standard suspension of barium sulfate in water.

MIL-DTL-17111C Rust prevention

The transmission fluid shall

prevent the formation of rust.

MIL-DTL-17111C Corrosion

and oxidation stability

The finished fluid must encompass

both resistance to oxidation and protection of metal parts

against corrosion.

MIL-DTL-17111C Packaging

When packaging of materiel is to be performed by DoD or in-house

contractor personnel, these personnel need to contact the

responsible packaging activity to ascertain packaging

requirements. Packaging requirements are maintained by the

inventory control point’s packaging activities within the

military service or defense agency or within the military

service’s system command. Packaging data retrieval is

available from the managing military department’s or defense

agency’s automated packaging files, CD-ROM products, or by

contacting the responsible packaging activity.

MIL-SPEC, military

specification, military standard (MIL-STD) is a United States Defense

standard used to describe a product that meets specific performance and

manufacturing standards for equipment and chemicals.

Other non-defense government

organizations, technical organizations and industry may also use

military specifications are not just limited to The Department of

Defense, as other government organizations and Industry use them as

well.

Here is a Q&A from the Department of

Defense:

What is a performance spec?

A.

A performance specification states requirements in terms of the

required results with criteria for verifying compliance, but

without stating the methods for achieving the required results.

A performance specification defines the functional requirements

for the item, the environment in which it must operate, and

interface and interchangeability characteristics.

Q. What guidance have we given on how to write a performance

specification?

A. Writing performance specifications is not a new concept. We have

been teaching how to write performance requirements for years at

our specification training course. It has received extra

emphasis in our training on how to write Commercial Item

Descriptions. What is new is that we are now designating

documents as "performance specifications."

Q. If you have a performance spec that is MILSPEC, is a waiver needed?

A. No.

Q. Is it possible for a general specification to be designated as

performance and its associated specification sheets to be

designated as detail?

A. No. Since a general specification must be used together with a

specification sheet, the fact that the specification sheet is

detail requires the general specification also to be designated

as detail.

Q. Within the same family of specification sheets, is it possible for some

to be designated as detail and others to be performance?

A. Generally, no. The decision whether to convert a family of

specification sheets to performance specifications must be

consistent across-the-board. In some cases, however, the number

of specification sheets that must be converted to performance

specifications may be very large, making it difficult to convert

all of them at one time. In this situation, there may be a

temporary blend of detail and performance specification sheets

within the same document number series. This situation is

acceptable as long as the goal is to convert all of them to

performance specifications.

Q. Can a performance spec ever cite a detail spec as a requirement?

A. The citing of a detail spec as a requirement does not

automatically mean that a spec is not performance, but it is a

strong indicator that as spec may not be performance.

Performance specs should not cite any detail spec as a

requirement if it demands a specific design solution. But

performance specs may cite a detail spec if it relates to a

physical or operational interface requirement.

For example, it would be permissible to have a requirement in a performance engine

specification that required the engine to operate with specific

substances, such as lubricating oil or fuel, which conform to

detail specs. The requirement that the engine be able to operate

on a specific type of fuel is an operational interface

requirement and does not dictate the specific design of the

engine. However, it would not be permissible in a performance

spec to require the engine be made of certain materials or that

the various engine components conform to detail specs since such

requirements would dictate specific design solutions instead of

stating the performance expected.

Q. I'm writing a spec that describes a "kit."

Should

it be a detail (MIL-DTL-) or a performance (MIL-PRF-)

specification?

A. In general, the answer is that it will likely be a detail

specification; however, there can be exceptions. A spec for a

kit describes a collection of related items, such as adapters,

couplings, bags, tools, attachments, or accessories. A kit may

contain items for installing, testing, or starting up a system

or piece of equipment; it may be provided to equip an existing

system for specific functions; or it may be used to adapt

equipment to meet new or specialized conditions. If the spec

writer were careful to write all of the requirements for the

kit's contents in terms of form, fit, function, and interfaces,

and to cite only performance-type documents, the resulting spec

would support a MIL-PRF designation. As is frequently the case,

however, if one or more of the kit's components are described

using a specific design solution, Technical Data Package, MIL-DTL

type spec, or a non-government standard that contains detail

design requirements, the kit spec must be designated as a MIL-DTL.

The spec writer needs to keep in mind that all of the

requirements for all of the kits' components must be stated in

performance terms in order to produce a MIL-PRF.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.