Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

EMAIL US

DIRECT (215) 333-4187 OR (800) 887-2436 Ext. 224 or 211 CAGE CODE 9Y364

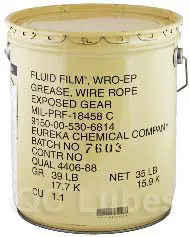

Fluid Film Gel

WRO EP Fluid Film Gel Information:

available in 35 lb. pails only

Permanently soft gel. Conforms to MIL-PRF-18458C.

Submarine Material Usage

Category-Limited-100°F Maximum Temperature.

Greenish black.

WRO-EP is recommended for the general maintenance of wire rope.

It provides

corrosion protection and lubrication for standing and running rigging, drag lines and bridge cable.

The high tackiness of WRO-EP minimizes throw-off on higher speed running rigging and provides higher resistance to water abrasion and washout when used in tidal areas.

Extreme pressure properties provide excellent

lubrication for both wire rope and open gear applications.

Rusty wire rope and cable should be first treated with FLUID FILM® Liquid A to attain maximum penetration.

Where a low viscosity material is desired for a slushing compound, the use of FLUID FILM® Gel WRL is recommended. This product also has extreme pressure properties.

WRO-EP Wire Rope Lubricant may be applied using a leather or lamb's wool glove. When a considerable length of wire is to be coated, it may be advantageous to apply as follows:

Form a cone of leather, about two feet long and six inches in diameter at the base. Both base and apex are left open with the wire rope passing through the apex. The apex is tightly lashed around the wire with marlin for about six inches. WRO-EP is applied to the wire with a rag, then the leather cone is dragged along the wire (or vice versa) so that the excess is scraped off into the cone, the remainder being well worked into the rope crevices.

The amount of material left on the wire can be regulated by adjusting the marlin lashing. Too heavy an application not only wastes material but also can result in throw-off, particularly in running cable.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.

Welcome! Thanks for visiting.